doi: 10.56294/hl2022143

ORIGINAL

Examining the Effect of Occupational Health and Safety Practices on Improving Workplace Safety Outcomes

Examinar el efecto de las prácticas de salud y seguridad en el trabajo en la mejora de los resultados de la seguridad laboral

Pooja Varma1

![]() , Mrutunjay Dash2

, Mrutunjay Dash2

![]() , Sagar V. Joshi3, Shardha Purohit4

, Sagar V. Joshi3, Shardha Purohit4

![]()

1JAIN (Deemed-to-be University), Department of Psychology. Bangalore, India.

2IMS and SUM Hospital, Siksha ‘O’ Anusandhan (Deemed to be University), Department of Paediatrics. Bhubaneswar, India.

3Nutan Maharashtra Institute of Engineering and Technology, Department of Electronics & Telecommunication, Talegaon Dabhade, India.

4Noida International University, School of journalism and Mass Communication (SJMC). Greater Noida, India.

Cite as: Varma P, Dash M, Sagar VJ, Purohit S. Examining the Effect of Occupational Health and Safety Practices on Improving Workplace Safety Outcomes. Health Leadership and Quality of Life. 2022; 1:143. https://doi.org/10.56294/hl2022143

Submitted: 20-08-2024 Revised: 27-10-2024 Accepted: 21-12-2024 Published: 22-12-2024

Editor:

PhD. Prof. Neela Satheesh

![]()

ABSTRACT

With an emphasis on important elements, such as safety regulations, training initiatives, hazard identification, employee involvement, and leadership dedication, the research investigates how occupational health and safety (OHS) practices might enhance workplace safety results. The research investigates the impact of successful OHS initiatives on workplace injury rates, given the importance of workplace safety. Surveys were used to obtain data on OHS procedures and safety outcomes from a sample of 9500 employees in various sectors. The IBM SPSS software version of 29.0 was utilized and data were analyzed using independent t-tests to compare safety outcomes between organizations with different levels of OHS adherence, descriptive statistics to summarize the features of the data, and chi-square tests to assess the relationship between safety practices and injury rates. According to the results, there is a substantial correlation between reduced injury rates and important elements like thorough safety training, frequent risk assessments, and active employee participation in safety procedures. Additionally, when compared to organizations with less comprehensive OHS practices, those that exhibit leadership commitment, cultivate a strong safety culture, and follow industry-specific safety requirements have superior safety outcomes. To lower workplace accidents and the resulting financial and human consequences, the research highlights the significance of these critical elements. The results suggest that further research could explore the integration of technology in OHS practices and investigate the long-term impact of evolving safety regulations on workplace safety outcomes.

Keywords: Occupational Health And Safety (OHS); Workplace Safety; Financial And Human Consequences; Chi-Square Tests; Descriptive Statistics; Independent T-Tests.

RESUMEN

Haciendo hincapié en elementos importantes, como las normas de seguridad, las iniciativas de formación, la identificación de peligros, la participación de los empleados y la dedicación de los líderes, el estudio investiga cómo las prácticas de salud y seguridad en el trabajo (SST) pueden mejorar los resultados de la seguridad en el lugar de trabajo. Dada la importancia de la seguridad en el lugar de trabajo, el estudio analiza el impacto de las iniciativas de salud y seguridad en el trabajo que han tenido éxito en los índices de lesiones en el lugar de trabajo. Se utilizaron encuestas para obtener datos sobre procedimientos de salud y seguridad en el trabajo y resultados de seguridad de una muestra de 9500 empleados de diversos sectores. Se utilizó el programa informático IBM SPSS versión 29.0 y se analizaron los datos mediante pruebas t independientes para comparar los resultados de seguridad entre organizaciones con distintos niveles de adhesión a la PRL, estadísticas descriptivas para resumir las características de los datos y pruebas chi-cuadrado para evaluar larelación entre las prácticas de seguridad y los índices de lesiones. Según los resultados, existe una correlación sustancial entre la reducción de los índices de lesiones y elementos importantes como la formación exhaustiva en seguridad, las evaluaciones frecuentes de riesgos y la participación activa de los empleados en los procedimientos de seguridad. Además, en comparación con las organizaciones con prácticas de salud y seguridad en el trabajo menos exhaustivas, las que muestran un compromiso de liderazgo, cultivan una cultura de seguridad sólida y cumplen los requisitos de seguridad específicos del sector obtienen mejores resultados en materia de seguridad. Para reducir los accidentes laborales y sus consecuencias económicas y humanas, el estudio subraya la importancia de estos elementos críticos. Los resultados sugieren que en futuras investigaciones se estudie la integración de la tecnología en las prácticas de salud y seguridad en el trabajo y se estudien las repercusiones a largo plazo de la evolución de la normativa de seguridad en los resultados de la seguridad en el lugar de trabajo.

Palabras clave: Salud y Seguridad en el Trabajo (SST); Seguridad en el Lugar de Trabajo; Consecuencias Económicas y Humanas; Pruebas Chi-Cuadrado; Estadísticas Descriptivas; Pruebas T Independientes.

INTRODUCTION

Occupational Health and Safety (OHS) includes common measures that protect workers’ health and reduce risk in the workplace.(1) Effective interventions in OHS policy and practice improve safety consciousness, minimize accident rates, and promote prevention in organizations.(2) Key practices include the identifying hazards, estimating the risk that the identifying hazards present, educating employees on the identified risks, employing Personal Protective Equipment (PPE), and ensuring compliance with risk regulation. Many researchers have shown that OHS has major advantages in enhancing worker output and satisfaction, and in decreasing costs related to work-related injuries and workers’ compensation.(3) However, these recognized benefits are still implemented with many limitations that constrain the optimum application of OHS practices within many industries. Variability in an organization’s commitment to safety policies leads to inconsistent safety outcomes, as differing levels of adherence impact the effectiveness of safety measures. Small business organizations particularly suffer from inadequate resource allocation and commitment due to prioritizing production output over investing in comprehensive employee safety measures.(4) Furthermore, compliance with OHS regulations can be viewed as a mere formality rather than an integrated, proactive strategy, reducing the effectiveness of safety measures.(5)

Another limitation is the gap between management-level safety policies and actual implementation at the operational level. Lack of communication, insufficient supervision, and failure to involve employees in safety programs and practices reduce the expected effectiveness of safety interventions. Moreover, in employment, OHS performance indicators are dominated by lagging indicators, such as injury rates, rather than leading indicators that point to potential risks.(6) Furthermore, existing OHS frameworks do not fully address the new dangers brought by changing working contexts, such as those related to automation, digital fatigue, and remote work.(7) Lastly, OHS programs frequently lack customized methods that take corporate culture and human error into consideration, even though behavioral and cultural elements have a major impact on safety results.(8) This research examines the way effective OHS programs affect the number of workplace injuries, considering the significance of workplace safety.

Related work

To enhance the transfer of learned material to the workplace, the research assessed additional treatments. The investigation was an initial experimental effort to assess whether changes affected migrant worker associations in a global construction effort. Training transfer was much improved when training programs were used with interventions included, according to data analysis.(9) By evaluating the association among mindfulness characteristics and occupational injuries and investigating an intermediary mechanism and environmental mediator of this connection, that research contributes to satisfying this requirement. These findings suggested that the characteristic of mindfulness was a useful interpersonal resource required for an efficient security-focused workplace and that it constitutes an essential indicator for security actions.(10) The investigation examined the way effective leadership affects followers’ workplace fulfillment in hospitality firms through mental safety and Green Human Resource Management (GHRM) techniques. That research discovered information supporting revolutionary management’s indirect impacts on work satisfaction through GHRM and mental safety.(11)

The research suggested a particularly intriguing reason for Organizational Citizenship Behaviors (OCBs) that deviates from the concept of Human Resources (HR) was work engagement. The findings imply that people with strong HR and significant amounts of optimism report improved work efficiency and OCBs as a consequence of the motivating value of work engagement.(12) To bridge the distinction between two important participation security administration tactics, like behavioral security and participation aesthetics. To provide a thorough description of participation security administration, it provides a summary of the concept, examined its history and essential components, and discusses unifying factors.(13) The investigation focused on the managerial interaction in a highly hazardous setting, emphasizing societal aspects including material, sentimental, and intellectual assistance. The findings indicated that knowledge support, which workers provide by supporting coworkers, has a major impact on their conduct, but psychological assistance is hard to customize as well as desired.(14)

The safety atmosphere, safety actions, and safety consequences of these social categories were examined in the research. For each group, there was an advantageous relationship between security actions and a secure culture. However, there were notable differences between managers and construction employees in the relationships between safety atmosphere and safety results between security actions and security results, indicating complementarity issues.(15) Indicators for workplace safety are presented in that research along with the methodology for choosing and prioritizing them based on expert evaluation and the group fuzzy analytic hierarchy process. The most crucial indications for the sustainable development of the workplace security system’s operation were the data that describe activities.(16) The research investigated the way workplace safety and wellness professionals perceive the possibility of accidents, with a particular emphasis on socioeconomic variables. The findings indicated that there are no appreciable variations in perceived hazards across men and women, but there are considerable variances based on maturity. Initially, in the building process, there were more disparities, but the general risk evaluations were consistent regardless of socioeconomic variations.(17)

METHOD

OHS procedures’ effects on workplace safety outcomes are investigated in this methodology. It examined important elements that increase worker safety and lower injury rates, such as safety training, danger identification, and leadership commitment.

Study Design

The research uses a quantitative, cross-sectional approach and polls 9 500 workers from a variety of industries to collect information on safety outcomes and OHS practices. The architecture makes it possible to investigate how important safety procedures affect injury rates and overall workplace safety results.

Data Collection

To effectively capture measures of compliance with OHS procedures and results of workplace safety, 9 500 workers from various industries were interviewed. That poll included questions about safety laws, training programs, danger identification, employee involvement, and leadership dedication to safety. Table 1 shows the demographic distribution of the employees in the OHS survey. Details concerning safety training and safety participation information, the frequency of risk assessment, and commerce compliance with the industry safety standards were obtained from the participants. Information about safety training and employee engagement in safety processes, as well as the frequency of risk assessments and commerce compliance with industry-specific safety requirements, were all supplied by the participants. To address variations of OHS and safety outcomes, measurements were taken considering the aspects of privacy and morality of the research methods. A special focus on obtaining broad participation from a range of sectors.

|

Table 1. Demographic Distribution of Employees in the OHS Survey |

|||

|

Demographic Characteristic |

Category |

Frequency (n) |

Percentage ( %) |

|

Gender |

Male |

5600 |

59 % |

|

Female |

3900 |

41 % |

|

|

Age Group |

18–45 years |

9125 |

96 % |

|

56+ years |

375 |

4 % |

|

|

Industry |

Manufacturing, Construction, Healthcare |

6700 |

70 % |

|

Others |

2800 |

30 % |

|

|

Years of Work Experience |

< 10 years |

7425 |

78 % |

|

20+ years |

2075 |

22 % |

|

|

Job Role |

Managerial/Leadership, Supervisory, Technical |

8650 |

91 % |

|

Administrative/Support |

850 |

10 % |

|

|

Education Level |

High School or Below |

4800 |

50 % |

|

Bachelor’s Degree or Above |

4700 |

50 % |

|

Statistical Analysis

Statistical analysis was conducted using IBM SPSS software version 29.0. Significant variations in injury rates were found when safety outcomes were compared amongst firms with different degrees of OHS adherence using independent t-tests. The data was compiled using descriptive statistics, which gave a summary of important aspects, including how frequently safety training and risk assessments are conducted. Chi-square tests were also used to determine the relationship between safety practices and the frequency of injuries and a strong result was established on activities that involve leadership commitment, regular risk assessments, active employee engagement, and lower injury rates. The finding thorough OHS procedures result in better safety results is supported by the analysis.

RESULT

The findings presented to establish a relationship between the implementation of effective OHS practices and enhanced workplace safety outcomes by employing a set of independent t-tests descriptive analysis and chi-square tests. It has been discovered that important elements, including leadership dedication, risk assessments and safety training lower injury rates and improve overall safety performance.

Descriptive Statistics for Summarizing Data Features

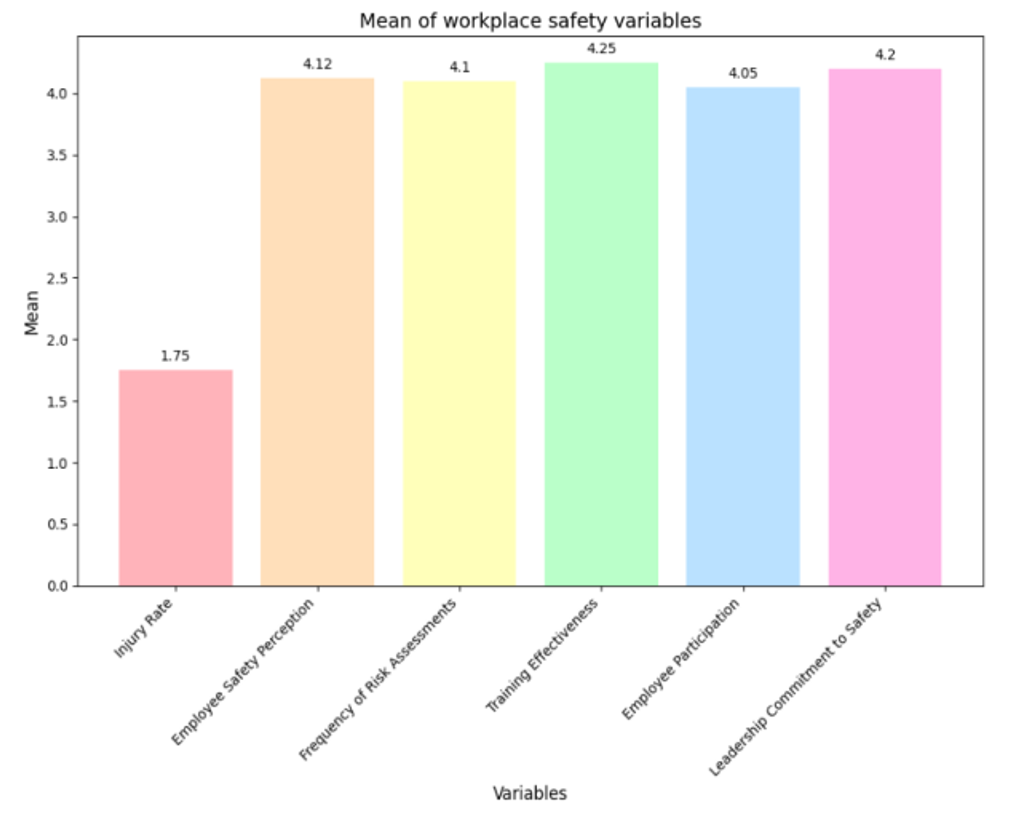

It is used to create a basic overview of the results, trends and variability of the variables related to workplace safety. With values ranging from 0 to 4,50, the injury rate represents only moderate occurrence of events at work with an average of 1,75 (SD=0,60). With scores ranging from 2,00 to 5,00 and a mean of 4,12 (SD = 0,45), employee safety perception indicates that overall, workers have a generally positive opinion of workplace safety. With a range of 1,00 to 5,00 and a high mean of 4,10 (SD = 0,50), the frequency of risk assessments again demonstrates consistency in assessments but considerable variance in perceived frequency. With values ranging from 2,50 to 5,00, training effectiveness has a mean of 4,25 (SD = 0,40), indicating that training programs are usually regarded as successful. Although there is significant variation in responses, as indicated by the lowest of 1,00 and maximum of 5,00, employee participation in safety programs has an overall positive engagement mean of 4,05 (SD = 0,55). The majority of employees perceive a leader’s commitment to safety, while there is significant variance, as seen by the leadership commitment to safety mean of 4,20 (SD = 0,50), which ranges from 2,00 to 5,00. Table 2 shows how employees generally accept workplace safety in their workplace while revealing that opinions differ across other important aspects. Figure 1 depicts the result of workplace safety variables in terms of mean.

|

Table 2. Descriptive Statistics of Workplace Safety Variables |

||||

|

Variable |

Mean (M) |

Standard Deviation (SD) |

Minimum |

Maximum |

|

N=9500 |

||||

|

Injury Rate |

1,75 |

0,60 |

0 |

4,50 |

|

Employee Safety Perception |

4,12 |

0,45 |

2,00 |

5,00 |

|

Frequency of Risk Assessments |

4,10 |

0,50 |

1,00 |

5,00 |

|

Training Effectiveness |

4,25 |

0,40 |

2,50 |

5,00 |

|

Employee Participation |

4,05 |

0,55 |

1,00 |

5,00 |

|

Leadership Commitment to Safety |

4,20 |

0,50 |

2,00 |

5,00 |

Independent t-test for Comparing Workplace Safety Outcomes across Groups

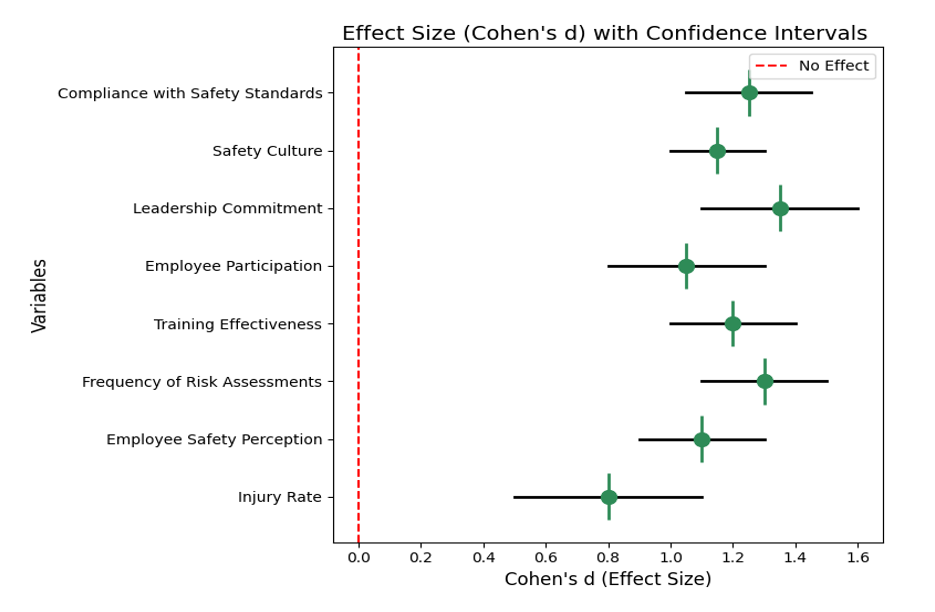

The differences in workplace safety outcomes between groups with high and low adherence to OHS procedures were assessed using an independent t-test. The results, which are summed together in Table 3, show that OHS adherence has a major influence because there are significant differences across all variables (p-values <0,001). With a substantial effect size Cohen’s d value of 0,80 and a t-value of 12,34, the high OHS adherence group reported substantially fewer injury rates outcomes, mean of 1,25, SD of 0,50 than the reduced adherence group (M = 2,15, SD = 0,70). The high adherence group (M = 4,50, SD = 0,40) had a significantly greater sense of employee safety than the low adherence group (M = 3,80, SD = 0,60), with a t-value of 15,67 and an effect size of 1,10. Significant variations were also seen in the frequency of risk assessments (M = 4,75 vs. M = 3,65, t = 20,45, d = 1,30), training efficacy (M = 4,60 vs. M = 3,90, t = 17,25, d = 1,20), and employee engagement (M = 4,40 vs. M = 3,60, t = 14,80, d = 1,05). The greatest impacts were shown in leadership commitment (M = 4,70 vs. M = 3,80, t = 18,90, d = 1,35) and adherence to safety regulations (M = 4,80 vs. M = 3,95, t = 19,25, d = 1,25). These findings highlight how strong OHS adherence may lower injury rates, promote a positive safety culture, and improve overall workplace safety outcomes. The significant advantages are demonstrated by the enormous impact sizes. Figure 2 depicts the effect size with confidence intervals.

Figure 1. Outcome of Workplace Safety Variables

|

Table 3. Independent T-test Results for Workplace Safety Outcomes Across OHS Adherence Levels |

|||||||

|

Variable |

OHS Adherence Level |

Mean (M) |

Standard Deviation (SD) |

t-value |

Degrees of Freedom (df) |

p-value |

Effect Size (Cohen’s d) |

|

Injury Rate |

High |

1,25 |

0,50 |

12,34 |

9498 |

<0,001 |

0,80 |

|

Low |

2,15 |

0,70 |

|||||

|

Employee Safety Perception |

High |

4,50 |

0,40 |

15,67 |

9498 |

<0,001 |

1,10 |

|

Low |

3,80 |

0,60 |

|||||

|

Frequency of Risk Assessments |

High |

4,75 |

0,35 |

20,45 |

9498 |

<0,001 |

1,30 |

|

Low |

3,65 |

0,55 |

|||||

|

Training Effectiveness |

High |

4,60 |

0,30 |

17,25 |

9498 |

<0,001 |

1,20 |

|

Low |

3,90 |

0,50 |

|||||

|

Employee Participation |

High |

4,40 |

0,45 |

14,80 |

9498 |

<0,001 |

1,05 |

|

Low |

3,60 |

0,60 |

|||||

|

Leadership Commitment |

High |

4,70 |

0,35 |

18,90 |

9498 |

<0,001 |

1,35 |

|

Low |

3,80 |

0,50 |

|||||

|

Safety Culture |

High |

4,55 |

0,40 |

16,00 |

9498 |

<0,001 |

1,15 |

|

Low |

3,85 |

0,55 |

|||||

|

Compliance with Safety Standards |

High |

4,80 |

0,30 |

19,25 |

9498 |

<0,001 |

1,25 |

|

Low |

3,95 |

0,50 |

|||||

Chi-Square Test: Evaluating the Connection between Safety Practices and Injury Rates

To assess the connection between different safety procedures and occupational accident rates, the chi-square test was used. Significant correlations between several safety procedures and injury rates are revealed by the findings, which are displayed in Table 4. The deprived completion rate of safety training (≤50 %), for example, has a chi-square value of 10,25 (p = 0,001), indicating that insufficient training is substantially linked to increased injury rates. In a similar vein, there was a significant correlation between the frequency of risk assessments and greater injury rates (χ² = 8,00, p = 0,005). Both leadership commitment to safety (χ² = 9,50, p = 0,002) and employee engagement in safety efforts (χ² = 6,75, p = 0,009) were shown to have significant relationships with injury rates, underscoring the significance of strong leadership and active participation in injury mitigation. Several other characteristics also had statistically significant associations with injury rates, including hazard identification (χ² = 7,20, p = 0,007), safety audits (χ² = 5,50, p = 0,019), employee input on safety (χ² = 6,00, p = 0,014), and adherence to safety standards (χ² = 4,30, p = 0,038). These findings indicate that for these safeguard measures, the steady methods of reducing work-related incidences and that effective, and recurrent safety measures are crucial to maintaining a protective workplace.

Figure 2. Effect Size of the Independent t-test with Confidence Intervals

|

Table 4. Chi-Square Test for the Relationship between Safety Practices and Injury Rates |

||||||

|

Variable |

Category |

Observed Frequency |

Expected Frequency |

Chi-Square (χ²) |

Degrees of Freedom (df) |

p-value |

|

Safety Training Completion |

Low (≤50 %) |

2500 |

2300 |

10,25 |

1 |

0,001 |

|

High (>50 %) |

7000 |

7100 |

||||

|

Frequency of Risk Assessments |

Infrequent |

3200 |

3100 |

8,00 |

1 |

0,005 |

|

Frequent |

6300 |

6400 |

||||

|

Employee Participation in Safety |

Low (≤50 %) |

3000 |

2900 |

6,75 |

1 |

0,009 |

|

High (>50 %) |

6500 |

6600 |

||||

|

Leadership Commitment |

Low |

2000 |

1900 |

9,50 |

1 |

0,002 |

|

High |

7500 |

7600 |

||||

|

Hazard Identification |

Low |

2800 |

2700 |

7,20 |

1 |

0,007 |

|

High |

6700 |

6800 |

||||

|

Safety Audits |

Infrequent |

3300 |

3200 |

5,50 |

1 |

0,019 |

|

Frequent |

6200 |

6300 |

||||

|

Employee Feedback on Safety |

Low |

2900 |

2800 |

6,00 |

1 |

0,014 |

|

High |

6600 |

6700 |

||||

|

Compliance with Safety Standards |

Low |

2600 |

2500 |

4,30 |

1 |

0,038 |

|

High |

6900 |

7000 |

||||

DISCUSSION

The data from the descriptive statistics, t-tests, and chi-square tests give the necessary information on safety practices and safety outcomes in the workplace. The descriptive statistics reveal high mean values about leadership commitment to safety (M = 4,20), adequacy and utility of safety training (M = 4,25), and employee-related positive safety climate (M = 4,12). The workforce can have different manners, as removed from the large spread, especially as it relates to injury rate (M = 1,75) and their level of participation in safety measures. The findings of independent t-tests demonstrate how important OHS adherence is to enhancing safety results. Higher safety perceptions, involvement, and efficacy across a range of safety behaviors were reported by workers in high OHS adherence groups, along with noticeably reduced injury rates (M = 1,25 vs. M = 2,15). Based on these findings, compliance with OHS leads to an upright safety climate and enhances general safety outcomes. Chi-square testing is also used on the injury rates and safety procedures, and both, confirm the relationship with Employee involvements in safety courses, lack of risk analysis, and poor safety classes (completion rate ≤50 %) were significantly related to injuries. Moreover, there was evidence that showed leadership commitment in achieving lower numbers of injuries. This result supports the need to utilize multifaceted safety action plans that include systems’ failure risk assessment, repeated safety instructions, and engaging the employees after implementing safety alterations within the workplace to minimize workplace accidents while raising the level of safety amongst the employees. The findings suggest that the safety rules and regulations should be enforced rigorously and systematically in the organization.

CONCLUSION

The workplace health and safety outcomes enhanced OHS practices. Key components, which include initial safety orientation, periodic safety evaluations, and employee engagement, supported dramatically lower incidences of injury. Moreover, the organizations that provided leadership commitment, safety culture, and compliance with the regulations of the safety industry received enhanced safety outcomes. These results cast light on the need for organizing workplace safety with proactive, multifaceted, leadership support that involves the adoption of frequencies of safety training and active employee participation. Focusing on these fundamental procedures might help firms drastically reduce workplace accidents, which would eventually preserve both financial resources and life. The research is constrained by the utilization of self-reported data, which could be subject to biases like memory bias or social desirability bias. Future research could investigate how technology can improve OHS practices and also examine the impacts that new safety standards would have over a long period as a reference for the aspiration of improving OHS.

REFERENCES

1. Bayram M, Ünğan MC. The relationships between OHS preventioncosts, OHSMS practices, employeesatisfaction, OHS performance and accidentcosts. TotalQuality Management & Business Excellence. 2020 Aug 17;31(11-12):1325-44. https://doi.org/10.1080/14783363.2018.1480897

2. Guerin RJ, Toland MD. Anapplication of a modified theory of planned behavior model to investigate adolescents’ job safety knowledge, norms, attitude and intention to enact workplace safety and healthskills. Journalof safety research. 2020; 72:189-98. https://doi.org/10.1016/j.jsr.2019.12.002

3. Wong TK, Man SS, Chan AH. Critical factors for the use or non-use of personal protective equipment amongst construction workers. Safety science. 2020; 126:104663. https://doi.org/10.1016/j.ssci.2020.104663

4. Nnaji C, Karakhan AA. Technologies for safety and healthmanagement in construction: Current use, implementationbenefits and limitations, and adoptionbarriers. JournalofBuildingEngineering. 2020 May 1;29:101212. https://doi.org/10.1016/j.jobe.2020.101212

5. Mei Q, Wang Q, Liu S, Zhou Q, Zhang J. Effects of organizational safety on employees’ proactivity safety behaviors and occupational health and safety management systems in Chinese high-risk small-scale enterprises. International Journal of Occupational Safety and Ergonomics. 2020 Jan 2;26(1):101-11. https://doi.org/10.1080/10803548.2018.1470287

6. Zwetsloot G, Leka S, Kines P, Jain A. Vision zero: Developing proactive leading indicators for safety, health and wellbeing at work. Safety Science. 2020 Oct 1;130:104890. https://doi.org/10.1016/j.ssci.2020.104890

7. Costantino F, Falegnami A, Fedele L, Bernabei M, Stabile S, Bentivenga R. New and emerging hazards for health and safety within digitalized manufacturing systems. Sustainability. 2021 Oct 1;13(19):10948. https://doi.org/10.3390/su131910948

8. Tetzlaff EJ, Goggins KA, Pegoraro AL, Dorman SC, Pakalnis V, Eger TR. Safety culture: a retrospective analysis of occupational health and safety mining reports. Safety and health at work. 2021 Jun 1;12(2):201-8. https://doi.org/10.1016/j.shaw.2020.12.001

9. Hussain R, Pedro A, Lee DY, Pham HC, Park CS. Impact of safety training and interventions on training-transfer: Targeting migrant construction workers. International journal of occupational safety and ergonomics. 2020 Apr 2. https://doi.org/10.1080/10803548.2018.1465671

10. Kao KY, Thomas CL, Spitzmueller C, Huang YH. Beingpresent in enhancing safety: Examiningtheeffectsofworkplace mindfulness, safety behaviors, and safety climateon safety outcomes. Journalof Business and Psychology. 2021 Feb;36(1):1-5. https://doi.org/10.1007/s10869-019-09658-3

11. Moin MF, Omar MK, Wei F, Rasheed MI, Hameed Z. Green HRM and psychological safety: How transformational leadership drives follower’s job satisfaction. Current issues in Tourism. 2021 Aug 18;24(16):2269-77. https://doi.org/10.1080/13683500.2020.1829569

12. Ozyilmaz A. Hope and human capital enhance job engagement to improve workplace outcomes. Journal of Occupational and Organizational Psychology. 2020 Mar;93(1):187-214. https://doi.org/10.1111/joop.12289

13. Rost KA, Alvero AM. Participatory approaches to workplace safety management: bridging the gap between behavioral safety and participatory ergonomics. International journal of occupational safety and ergonomics. 2020 Jan 2. https://doi.org/10.1080/10803548.2018.1438221

14. Haas EJ. The role ofsupervisorysupportonworkers’ health and safety performance. Healthcommunication. 2020 Feb 23;35(3):364-74. https://doi.org/10.1080/10410236.2018.1563033

15. He C, McCabe B, Jia G, Sun J. Effects of safety climate and safety behavior on safety outcomes between supervisors and construction workers. Journal of construction engineering and management. 2020 Jan 1;146(1):04019092. https://doi.org/10.1061/(ASCE)CO.1943-7862.0001735

16. Janackovic G, Stojiljkovic E, Grozdanovic M. Selection of key indicators for the improvement of occupational safety system in electricity distribution companies. Safety science. 2020 May 1;125:103654. https://doi.org/10.1016/j.ssci.2017.07.009

17. Trillo-Cabello AF, Carrillo-Castrillo JA, Rubio-Romero JC. Perceptionofrisk in construction. Exploringthefactorsthatinfluenceexperts in occupationalhealth and safety. Safety Science. 2021 Jan 1;133:104990. https://doi.org/10.1016/j.ssci.2020.104990

FINANCING

No financing.

CONFLICT OF INTEREST

None.

AUTHORSHIP CONTRIBUTION

Conceptualization: Pooja Varma, Mrutunjay Dash, Sagar V. Joshi, Shardha Purohit.

Data curation: Pooja Varma, Mrutunjay Dash, Sagar V. Joshi, Shardha Purohit.

Formal analysis: Pooja Varma, Mrutunjay Dash, Sagar V. Joshi, Shardha Purohit.

Research: Pooja Varma, Mrutunjay Dash, Sagar V. Joshi, Shardha Purohit.

Methodology: Pooja Varma, Mrutunjay Dash, Sagar V. Joshi, Shardha Purohit.

Project management: Pooja Varma, Mrutunjay Dash, Sagar V. Joshi, Shardha Purohit.

Resources: Pooja Varma, Mrutunjay Dash, Sagar V. Joshi, Shardha Purohit.

Software: Pooja Varma, Mrutunjay Dash, Sagar V. Joshi, Shardha Purohit.

Supervision: Pooja Varma, Mrutunjay Dash, Sagar V. Joshi, Shardha Purohit.

Validation: Pooja Varma, Mrutunjay Dash, Sagar V. Joshi, Shardha Purohit.

Display: Pooja Varma, Mrutunjay Dash, Sagar V. Joshi, Shardha Purohit.

Drafting - original draft: Pooja Varma, Mrutunjay Dash, Sagar V. Joshi, Shardha Purohit.

Writing - proofreading and editing: Pooja Varma, Mrutunjay Dash, Sagar V. Joshi, Shardha Purohit.